R & D and equipment development

Grid Parity is Our Goal

We believe that through durable R & D investment and technology breakthroughs, Gold Stone will become one of the leaders of the photovoltaic industry. Our confidence is rooted in our restless technology innovations.

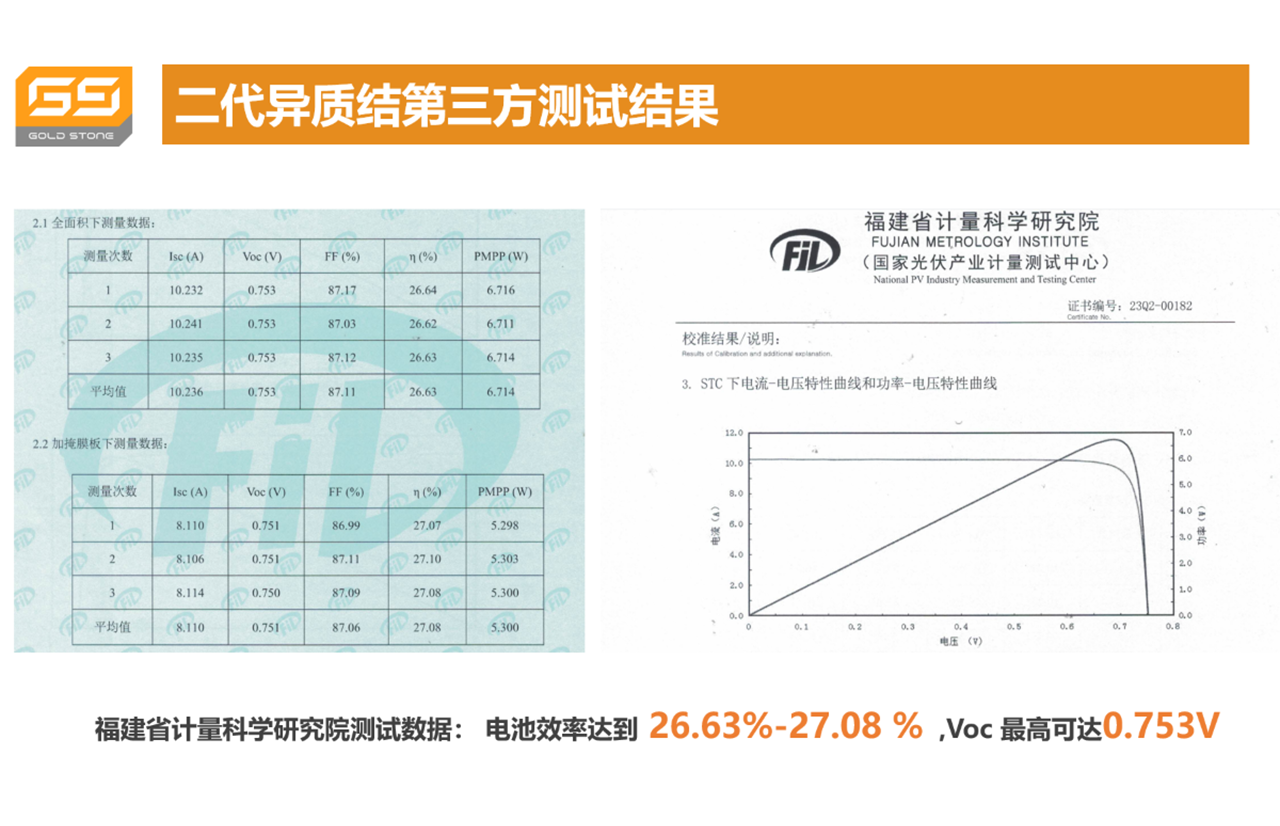

Conversion efficiency of the technology has been reached

Lowest end use cost

220 ° C or less

Advantages of HDT Solar Cells Technologies

1、Low processing temperature:All processes for HDT solar cells are carried out at temperatures below 220°C;

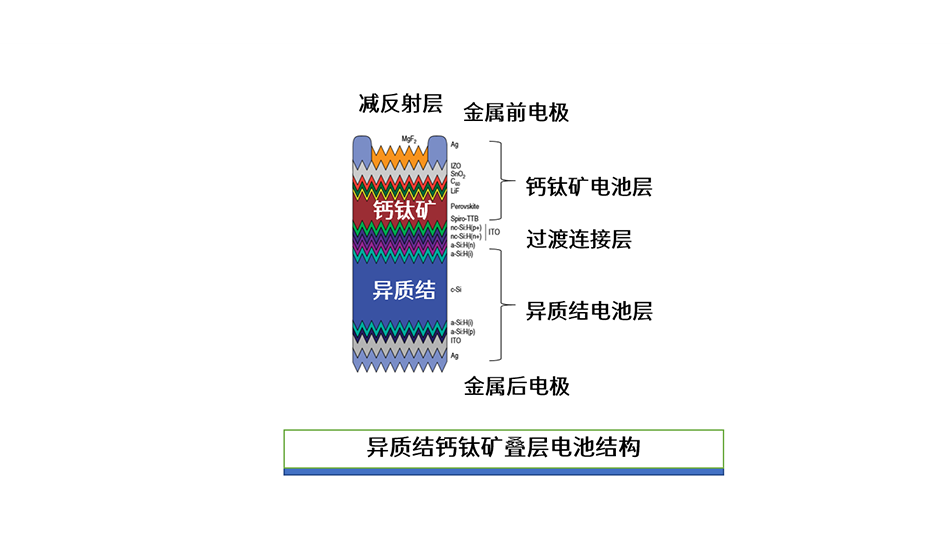

2、Hetero-junction emitter:Band engineering technology improves the quality of the amorphous silicon and widens its band gap, making the layer more transparent, resulting in Isc and Voc. The world record efficiency for this type of solar cells has reached to 26.3%;

3、Low power-temperature coefficient:The power-temperature coefficient of HDT solar cell is less than ~-0.24%/ºC, making it more suitable working in hot outdoor environment.

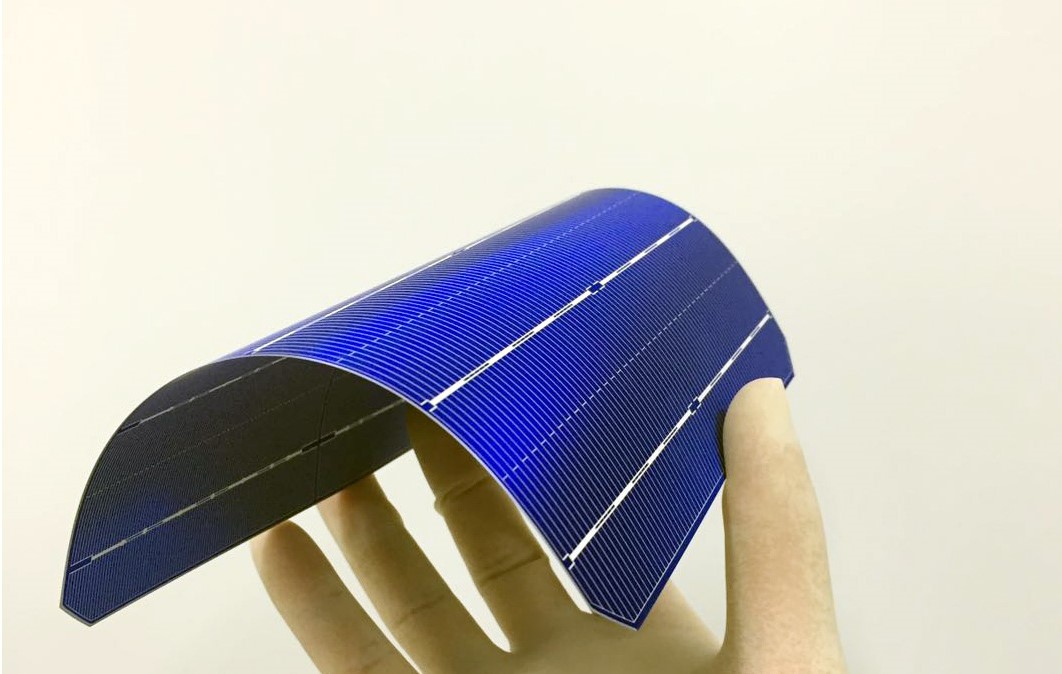

4、Readiness of flexible solar cells technology:GS-Solar developed the technology to fabricate the very thin silicon solar cells.

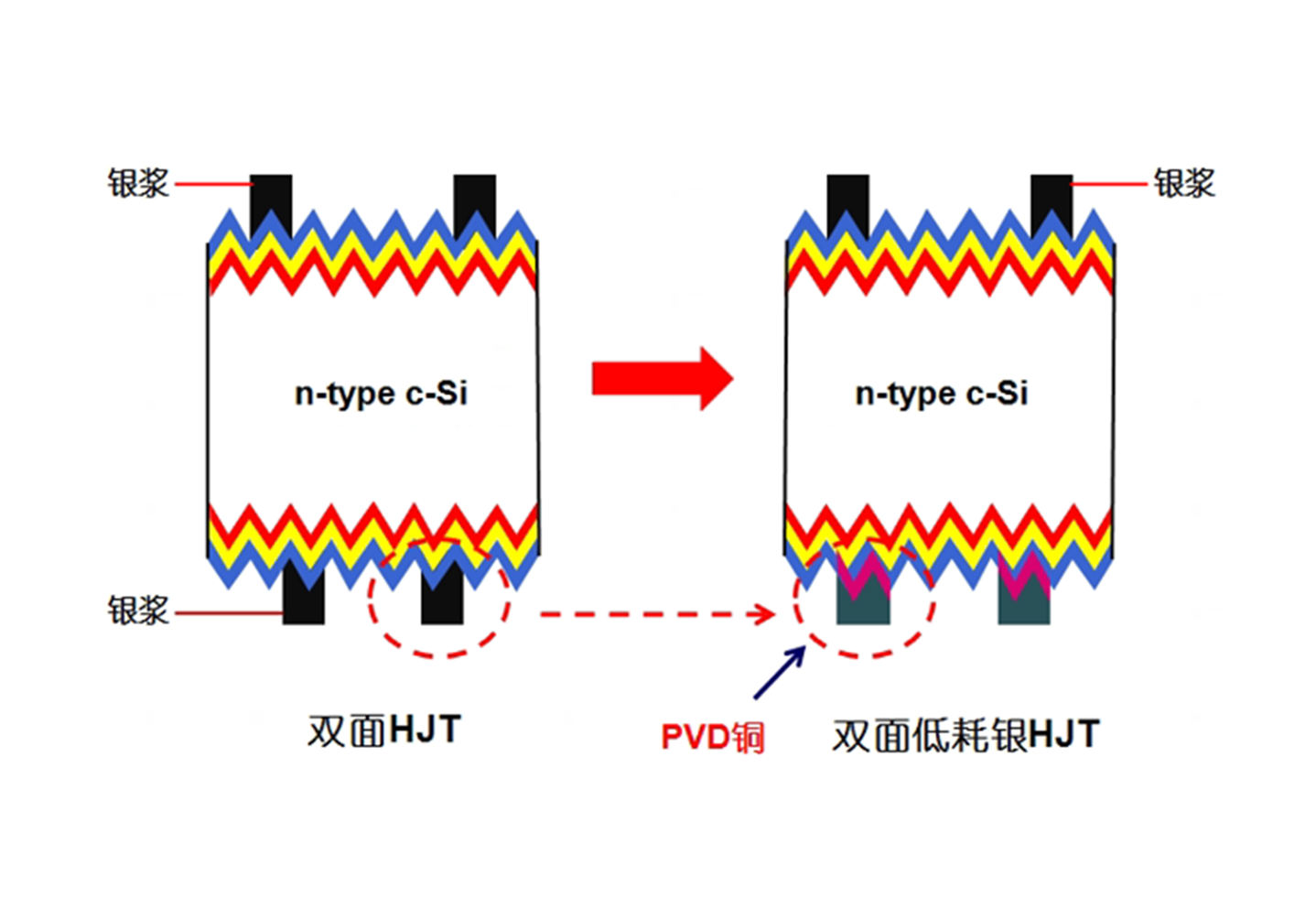

5、Double-sided module technology:HDT solar cell has a double-sided structure, which can receive the sunlight from both sides, well for making the glass-glass modules. With optimal positioning on the ground, the modules could generate ~10% more output power.

Principle of Lowest Cost

Seek to provide the end users of our solar cells with the lowest TCO (total cost of ownership).

Seek to provide our clients the highest ROI (return on investment) on a complete solar cell production line.

Reduce cost without making any compromises on high quality

Road Map for Increasing Conversion Efficiency of HDT Solar Cells

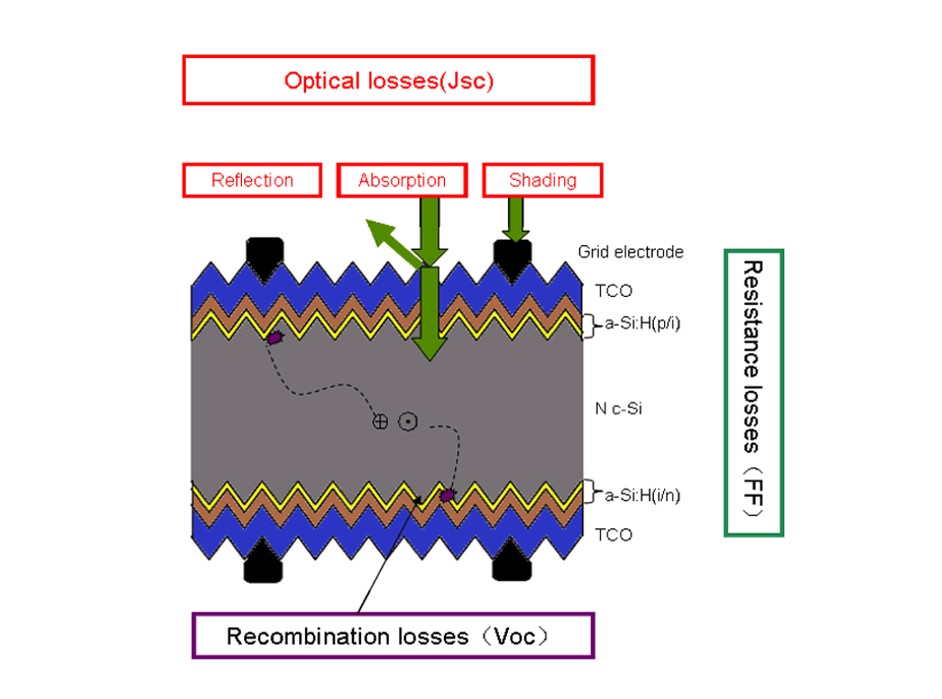

1、Reduction of Optical Loss:Reduce the textured surface reflection / Reduce the light absorption by TCO layer and amorphous silicon / Decrease the grid covering area by increasing its aspect ratio

2、Reduction of Surface Recombination Velocity:Improve the cleaning process for textured surface/Optimize the doping concentration of the doped amorphous silicon/Improve the quality of intrinsic layer

3、Reduction of Series Resistance:Increase the conductivity of TCO layer/Reduce the contact resistance between TCO layer and doped amorphous silicon

R&D Competence

Photovoltaic industry is growing exponentially and the competition in the industry is heated up. Only the companies who possess strong R&D and innovation competence can become global industry leaders.